- Home

- Products

- Fire resistant collars

- MG2-A

- Installation

MG2-A - Installation

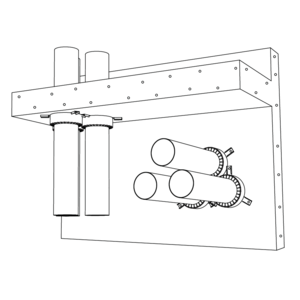

Installation in rigid wall and floor

The product was tested and approved in:

- see the classification overview in the Declaration of Performance.

- Mounting is authorised in supporting constructions with a thickness and/or density equal or superior to the supporting construction used during the test, as described in EN 1366-3.

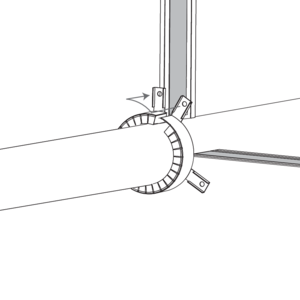

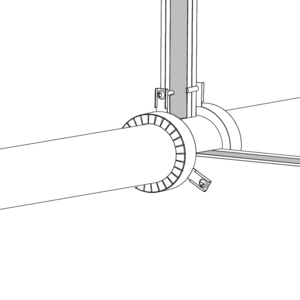

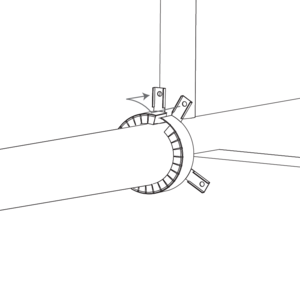

Keep one end of the collar in place with one hand whilst bending the collar around the pipe with the other hand.

Click the wall anchors into each other, right anchor on top of the left one.

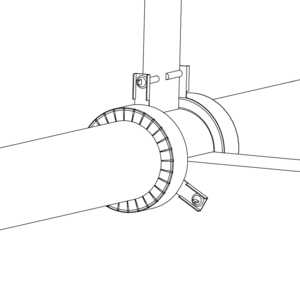

Click the wall anchors into each other, right anchor on top of the left one.

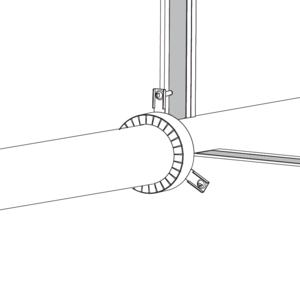

Reinforced concrete: place expander bolts in the pre-drilled holes Ø 6mm and fasten them. Aerated concrete: fix with universal M6 screws.

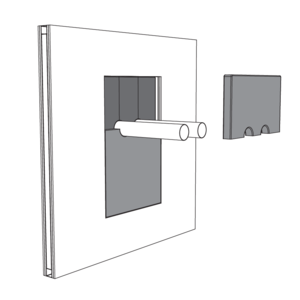

Place a collar on the other side in the same way.

Apply the label nearby the collar.

Place a collar on the other side in the same way.

Apply the label nearby the collar.

Installation in flexible wall (metal stud gypsum plasterboard wall)

The product was tested and approved in:

- see the classification overview in the Declaration of Performance.

- Mounting is authorised in supporting constructions with a thickness and/or density equal or superior to the supporting construction used during the test, as described in EN 1366-3.

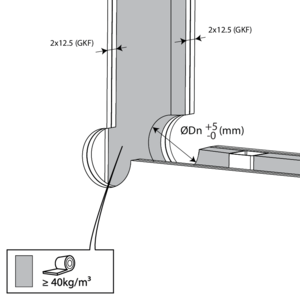

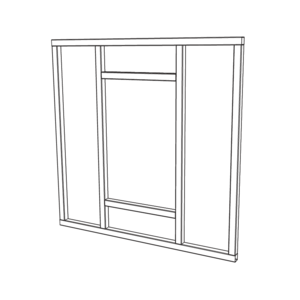

Fix two gypsum boards type F with a tickness of 12,5 mm to one side of the metal stud wall.

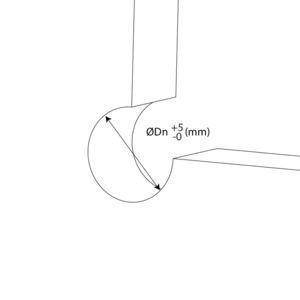

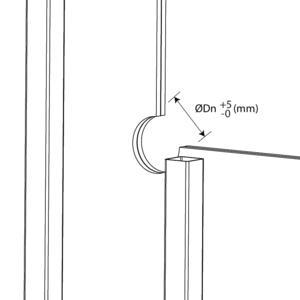

Provide an installation opening of ØDn mm.

Provide an installation opening of ØDn mm.

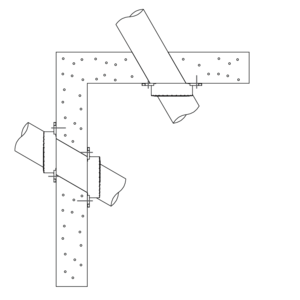

Installation in flexible and rigid wall, sealing with rigid rock wool boards with coating

The product was tested and approved in:

- see the classification overview in the Declaration of Performance.

- Mounting is authorised in supporting constructions with a thickness and/or density equal or superior to the supporting construction used during the test, as described in EN 1366-3.

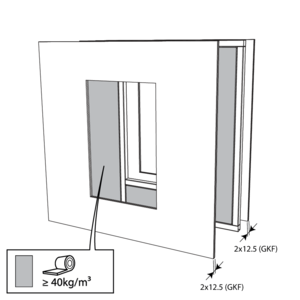

Fix two gypsum plasterboards type F of 12,5 mm thickness to each side of the metal studs and insulate the wall with 40 mm mineral wool, 40 kg/m³.

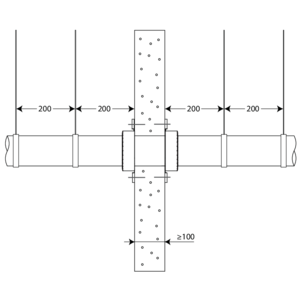

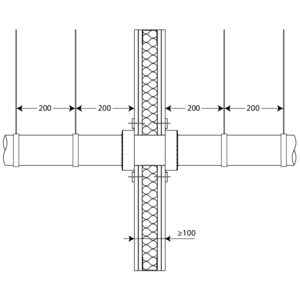

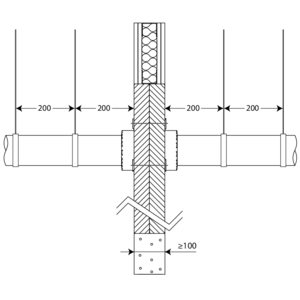

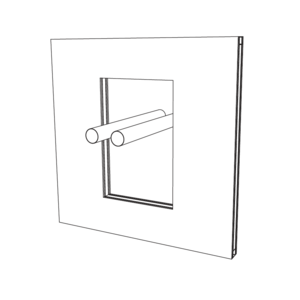

Place the plastic pipe(s). The distances between the pipes and the edges of the seal are min. 100 mm.

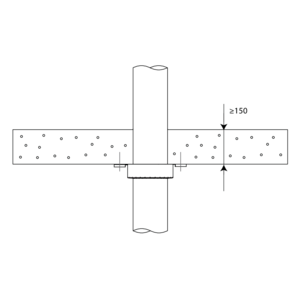

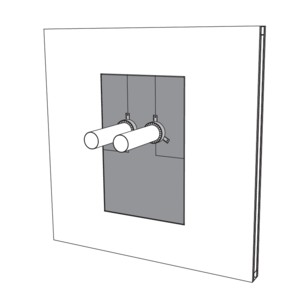

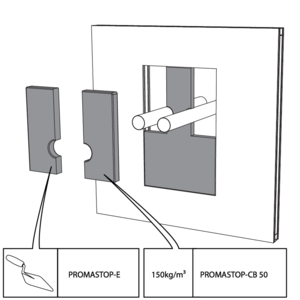

Fix a stone wool board of min. 50 mm thickness with fire resistant coating on one side (type PROMASTOP-CB 50) around the fire collars. Use a saw or knife to dimension the stone wool boards. Apply endothermic coating (type PROMASTOP-E) on the lateral sides, as well as on the joints.

Put the second stone wool board of min. 50mm thickness around the pipes. Avoid the joints from coinciding. Apply endothermic coating (type PROMASTOP-E) on the lateral sides, as well as on the joints.

General remarks

- The installation must comply with the installation manual and the classification report.

- The pipe must be supported in order to guarantee the well-functioning of the sealing during a fire. Supports and fastenings should be realised according to the rules of good craftsmanship.

Open to innovation, closed to fire

back

Open to innovation, closed to fire

back