- Home

- Products

- Fire resistant collars

- MG2

- Installation

MG2 - Installation

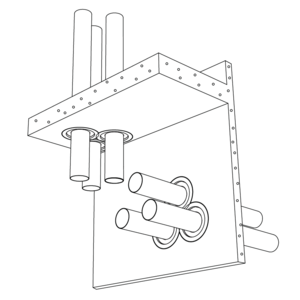

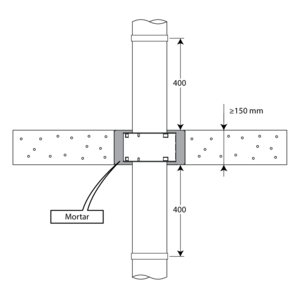

Installation in rigid wall and floor

The product was tested and approved in:

- see the classification overview in the Declaration of Performance.

- Mounting is authorised in supporting constructions with a density equal or superior to the supporting construction used during the test, as described in EN 1366-3.

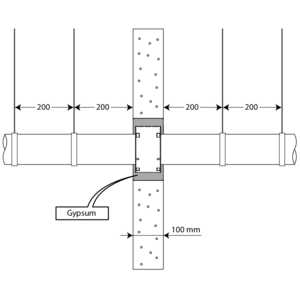

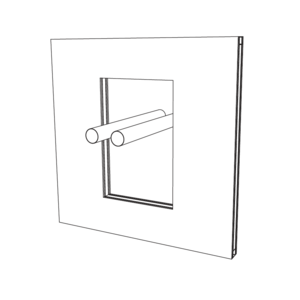

Installation in flexible wall (metal stud gypsum plasterboard wall)

The product was tested and approved in:

- see the classification overview in the Declaration of Performance.

- Mounting is authorised in supporting constructions with a density equal or superior to the supporting construction used during the test, as described in EN 1366-3.

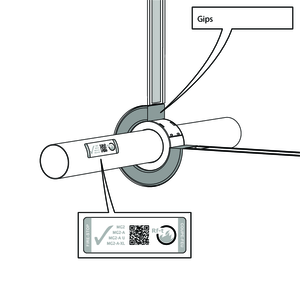

Fix two gypsum boards type F with a tickness of 12,5 mm to one side of the metal stud wall.

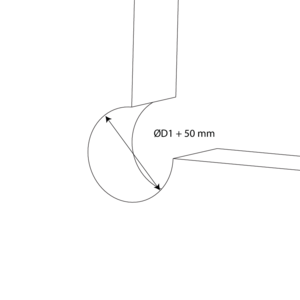

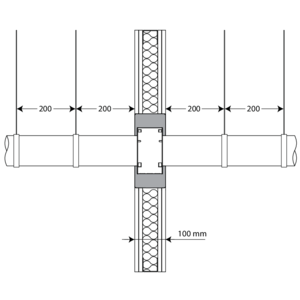

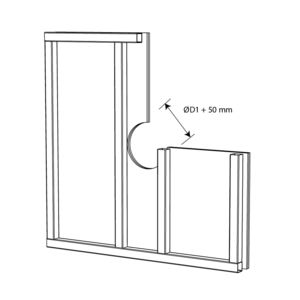

Provide a min. Installation opening in the wall of ØD1 + 50 mm.

Provide a min. Installation opening in the wall of ØD1 + 50 mm.

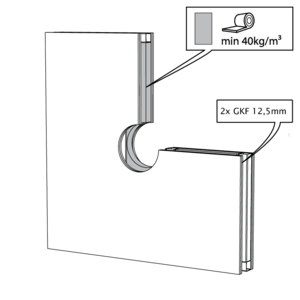

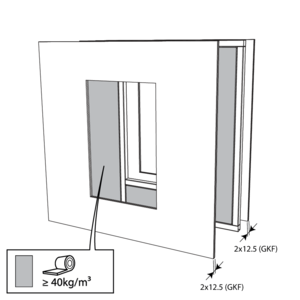

Installation in flexible and rigid wall, sealing with rigid rock wool boards with coating

The product was tested and approved in:

- see the classification overview in the Declaration of Performance.

- Mounting is authorised in supporting constructions with a density equal or superior to the supporting construction used during the test, as described in EN 1366-3.

Fix two gypsum plasterboards type F of 12,5 mm thickness to each side of the metal studs and insulate the wall with 40 mm mineral wool, 40 kg/m³.

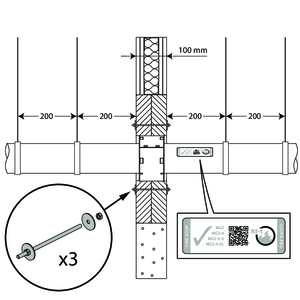

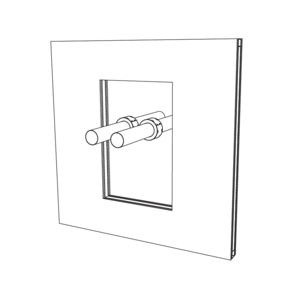

Place the plastic pipe(s). The distances between the pipes and the edges of the seal are min. 100 mm.

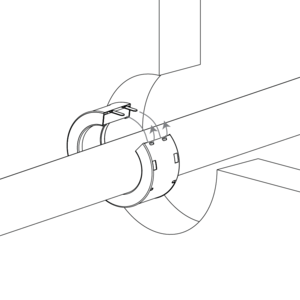

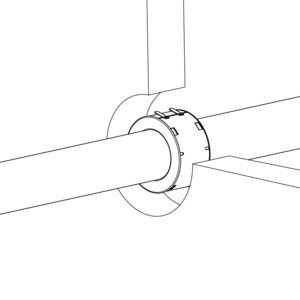

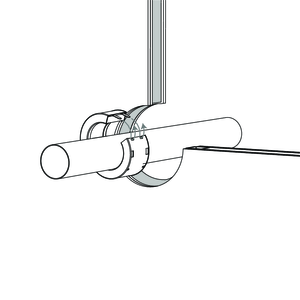

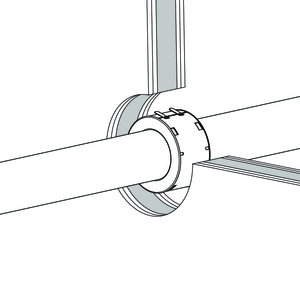

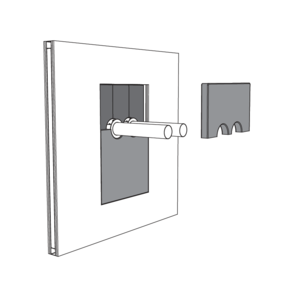

Place the built-in fire collars around the pipes by removing the label and fixing the collar by bending the fastening strips. Position the collars in the middle of the wall thickness.

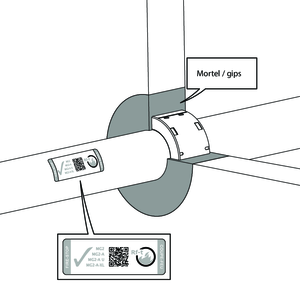

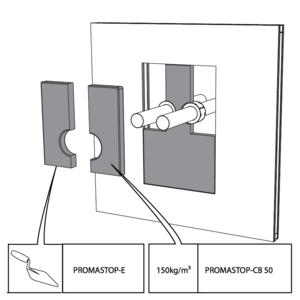

Fix a stone wool board of min. 50 mm thickness with fire resistant coating on one side (type PROMASTOP-CB 50) around the fire collars. Use a saw or knife to dimension the stone wool boards. Apply endothermic coating (type PROMASTOP-E) on the lateral sides, as well as on the joints.

General remarks

- The installation must comply with the installation manual and the classification report.

- The pipe must be supported in order to guarantee the well-functioning of the sealing during a fire. Supports and fastenings should be realised according to the rules of good craftsmanship.

Open to innovation, closed to fire

back

Open to innovation, closed to fire

back